- Ball Sizing

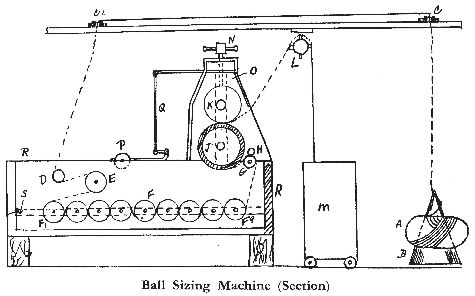

- BALL SIZINGConsists of three processes, sizing, drying and beaming. Used for coloured warps or for grey warps about 24's and lower, that are to be heavy sized, such as for heavy domestics, Wigans, etc. This system gives a leather-like feel to the yam and cloth, and is much used in the Rochdale district. The yam is not flattened as it is in tape sizing. For coloured work it is very suitable, owing to the shorter length, various colours, etc. The warp, in the form of a rope, is taken through the size trough (passing under and over rollers at the bottom). The excess size is squeezed out and the warp dried by passing over hot cylinders, then wound on to the weaver's beam. This system is very suitable for short warps, but is more expensive than tape sizing. A sectional view of the machine is shown in the illustration. A is the ball warp, it passes through eyes C and C1 down to rollers D and E in size box R. Then around rollers F. These rollers are free to move in groove S, and they press the yarn from roller F1 to F9. From the sizing, the yarn is squeezed between G and H, passes round J and between J and K, where it is squeezed again on to a guide; roller L and into box M. From M the yarn is taken to a drying machine and, after drying, it is reballed. The screw N regulates the pressure put upon the size by roller K

Dictionary of the English textile terms. 2014.